Inquire for this product.

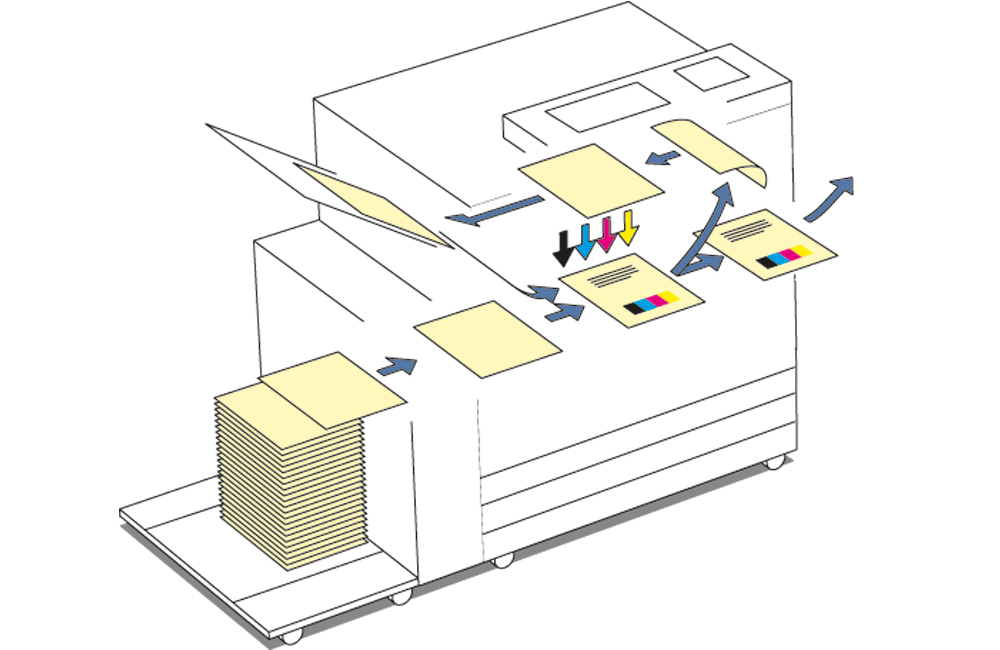

In cooperation with the renowned printer manufacturer Riso, BÖWE SYSTEC has succeeded in taking another decisive step towards process automation with The Bridge: This innovative configuration includes a special component, the ground-breaking “Bridge”, which connects a high-quality Riso color printer to the BÖWE SYSTEC inserting system Vario, allowing the realization of a White Paper Factory in the mailroom or even in office environments. After the documents have been printed on demand, they are automatically transported to the Vario inserting system, where they are then inserted – all without any manual intervention. Even very small batches or reprints can be processed easily. The highest integrity is guaranteed by a closed loop process along with complete monitoring of the document flow.

The inkjet printer is designed for high quality Simplex and Duplex color printing in A4-format (8 1/2" x 11") and enables cut-sheet processing with its high stacking capacity of up to 4,000 sheets. It allows for the immediate reprinting of documents as well as the processing of smaller jobs on demand. The printer’s “cold printing technology” allows the system to be ready for printing extremely fast. Furthermore, its low energy consumption in conjunction with oil-based ink makes the printer a cost-efficient end eco-friendly solution.

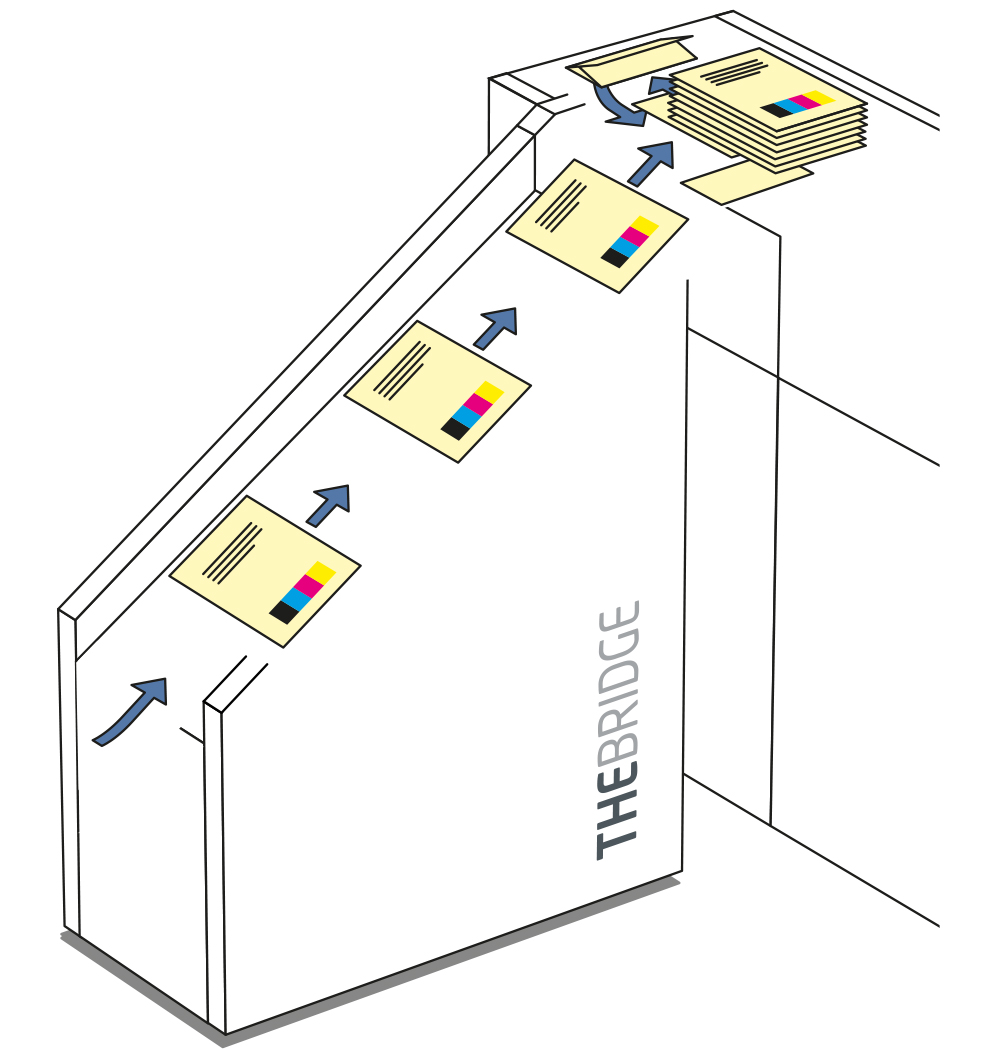

The printed documents are transported fully automatically to the integrated Vario inserting system via the actual “bridge” – without any manual intervention. An opaque cover prevents operator visibility and interventions from the outside and therefore guarantees 100 percent integrity. The Bridge automates all production steps from printing, document transportation to inserting and is ideally suited for handling highly confidential documents. Additionally, the high automation allows to reduce staff requirements to a minimum.

The proven BÖWE SYSTEC Vario inserting system processes DL, C6/5 (#10), C5 and B5 (6 x 9) applications reliably at a performance of up to 8,200 envelopes per hour. It is designed for assembling after folding (Single or C fold), two enclosure feeders enable processing different types of enclosures (more enclosure feeders are available upon request). Documents are inserted into the envelope safely, the envelope is closed reliably and stacked ready for mailing.

Download Brochure

Download Brochure

Back to Top